RELIABLE AND PREDICTABLE

- Excellent surface finish

- Secure edge line for consistent tool life

- High speed capabilities

RELIABLE AND PREDICTABLE

LOWER COST PER PART

Application

Hard part turning is usually a finishing or semi-finishing process with high dimensional accuracy and surface quality requirements. Typical machining challenges with these materials are surface and dimensional tolerance demands with competitive tool life.

Materials

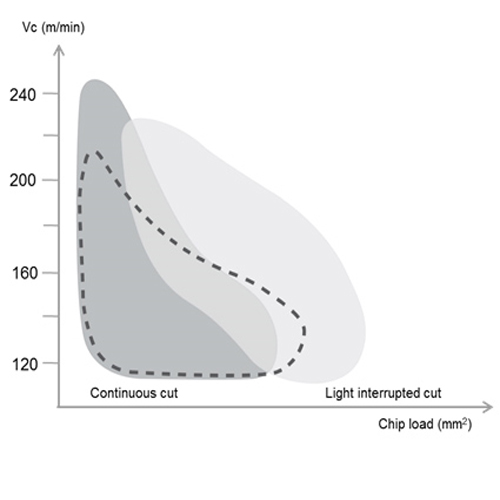

![]() CB7105 for continuous cut, smaller depth of cut, and smaller chip loads at high speed

CB7105 for continuous cut, smaller depth of cut, and smaller chip loads at high speed

![]() CB7115 Continuous to light interrupted cut or larger chip loads at medium to high speed

CB7115 Continuous to light interrupted cut or larger chip loads at medium to high speed

![]() CB7015

CB7015

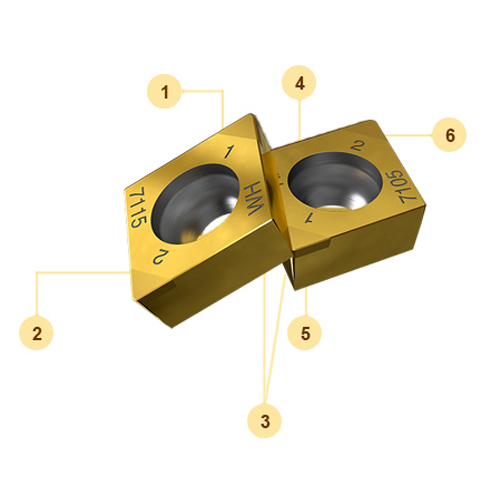

PRODUCT VARIANTS

CB7105

Use CB7105 for continuous cut, smaller depth of cut and smaller chip loads at high speed.

CB7115

Use CB7115 for continuous to light interrupted cut or larger chip loads at medium to high speed.