RAISING PRODUCTIVITY IN THE AEROSPACE INDUSTRY

Challenge: How to meet the demands of machining titanium airframe components? Solution: Employ tailored tooling solutions that can increase production rates and lower costs.

In the aerospace industry’s drive to reduce weight and total costs, titanium alloys are commonly used for major components within airframes, engines and landing gear, a practice that has grown steadily since the 1960s in both commercial and military airframes. As well as meeting the challenges of titanium, which is difficult to machine, aircraft component manufacturers want to make considerable improvements in productivity to cut overall costs.

Airframe structural components range from complex forged wing structures to landing gear components, as well small critical fasteners, springs and hydraulic tubing. Trends in airframe components have moved to single large structures rather than assemblies, and this demands more productive and stable machining processes. Frame components often contain features such as deep pockets, and producing these pockets requires stable, anti-vibration machining processes. Producing deep pockets often requires tools for machining with long gauge lengths.

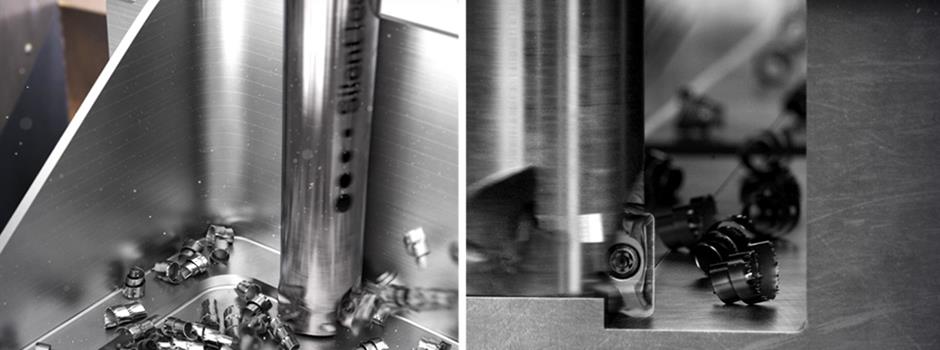

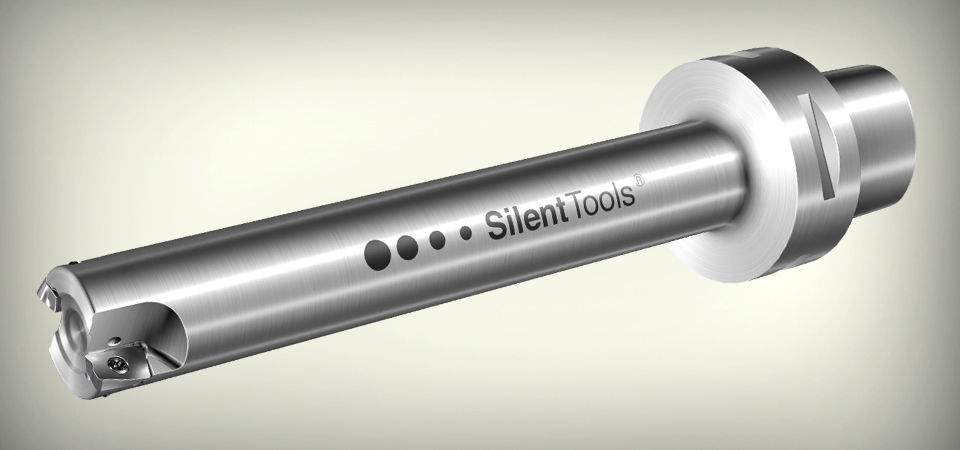

Sandvik Coromant, with its comprehensive experience of aerospace component machining, has developed a range of tooling solutions such as the CoroMill 390® with integrated Silent Tools™ technology that contribute to improved productivity while securing optimal functionality, thus reducing production costs when machining with long gauge lengths. Silent Tools incorporate a unique dampening technology that cuts potentially damaging vibrations that may affect the quality of the machining process.

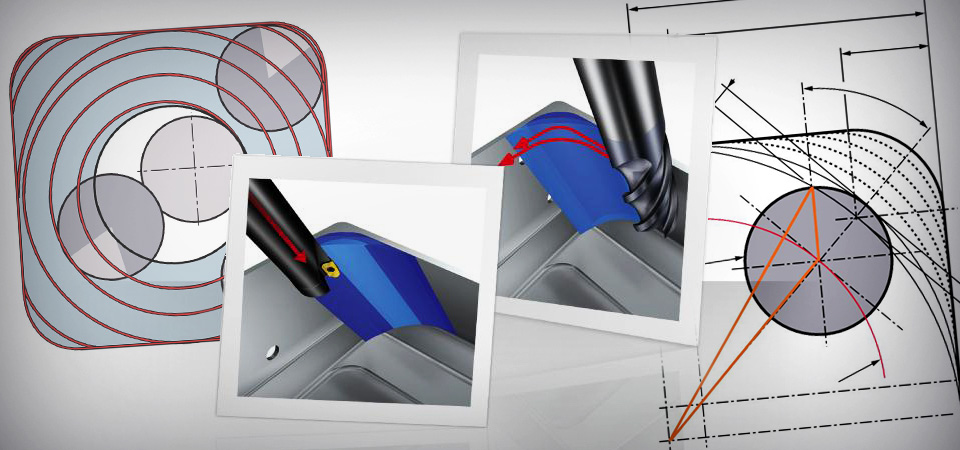

CoroMill 390 covers many applications with a large, versatile programme, including cutter versions for shoulder milling and long-edge milling. The cutters generate a good-quality 90-degree shoulder and are ideal for ramping and helical interpolation.

Silent Tools™

Integrating the Silent Tools technology into the CoroMill 390 concept enables trouble-free machining with long gauge lengths. Deep pockets or applications where long reach is needed can be machined with high productivity, low risk of vibrations and good process security. CoroMill 390 Silent Tools are now available for insert sizes 07 and 11. In general 07 inserts are more suitable for side milling applications while 11 is appropriate for roughing applications.

Titanium

Component designs vary significantly and require different machining strategies. In more challenging operations such as deep titanium pockets where long gauge lengths are required, a combination of premium cutting tools and best practice application knowledge is vital to be successful. Through its application support centres, Sandvik Coromant offers solutions tailored to the requirements of the manufacturer.

Sandvik Coromant has developed specific grades that can deal with the demands of titanium milling, which put the thermal, chemical and mechanical loads at the cutting edges close to the limits for any cutting tool material. Optimized grades S30T and S40T are available for face milling, shoulder milling, long-edge milling, plunging, high-feed milling, profiling and slot milling.

S30T combines the properties of micrograin carbide and a wear-resistant PVD coating. This enables very sharp cutting edges that resist fatigue and microscopic chipping and result in cutting edges that are preserved for longer times in cut at higher cutting speeds. S40T has the high toughness of cemented carbide with a thin CVD coating. This grade withstands vibration and other difficult cutting conditions for longer times in cut. The wear is predictable, making the cutting edge gradually duller without breaking.

Coromant Capto®

Tool holding has a great influence on the milling result. The larger the cutting depth, the more important the size and stability of the coupling become as the radial forces are considerable, such as when using shoulder and face mills, particularly with long gauge length cutters. Coromant Capto enables a common tooling platform regardless of the type of machine interface. As many machines have coolant pressures of 70–150 bars as standard, this supports the use of high-pressure coolant, which is important for titanium machining. In addition, the coupling provides stability and minimizes deflection for all cutter types and helps contribute to productivity and lowering of the overall cost per pocket.